Effectively Lower Friction With High-Quality Bearing Bushings

In the globe of equipment and mechanical systems, decreasing rubbing is a key goal for optimum efficiency and longevity. One efficient means to accomplish this is through the use of high-grade bearing bushings. These typically forgotten components play an important duty in minimizing friction and guaranteeing smooth procedure. Not all bearing bushings are produced equivalent, and the option of the appropriate kind can dramatically impact the efficiency of a system. So, how can one navigate through the substantial array of alternatives? What are the elements to think about when selecting and mounting bearing bushings? In this discussion, we will explore the significance of bearing bushings, the factors that affect rubbing in equipment, the advantages of utilizing top notch bushings, and supply functional ideas for selecting and installing them. Allow us embark on this trip to uncover exactly how premium bearing bushings can effectively decrease friction and improve the performance of equipment.

Value of Bearing Bushings

Bearing bushings play a vital role in making certain the smooth and effective operation of different mechanical systems. These little components are created to reduce friction and give support for turning or gliding shafts. By serving as a barrier in between moving parts, birthing bushings help to reduce damage, extend the life expectancy of equipment, and boost overall performance.

One of the key functions of bearing bushings is to decrease friction. Bearing bushings are made from materials with low coefficients of friction, such as bronze or self-lubricating polymers, which help to minimize this friction.

In addition to reducing friction, birthing bushings additionally give assistance and security to revolving or moving shafts. They assist to preserve appropriate alignment and avoid excessive movement or vibration, ensuring that the mechanical system runs efficiently and dependably. Without the support of bearing bushings, the shafts may be prone to misalignment, leading to increased rubbing, wear, and prospective damage to the entire system.

Variables Influencing Rubbing in Machinery

As the smooth operation and long life of equipment depend heavily on reducing rubbing, it is critical to comprehend the various factors that add to friction in machinery. Rubbing is the resistance that happens when two surface areas enter into contact and slide versus each other. It can bring about power loss, heat generation, and increased damage of device components. There are numerous elements that affect rubbing in equipment.

The first aspect is surface area roughness. When the surfaces of 2 components are rough, the call area boosts, resulting in higher rubbing. Polishing or lubing the surface areas can reduce friction by raveling the roughness.

The 2nd element is the kind and top quality of lubrication. Proper lubrication creates a slim film between the relocating surface areas, decreasing straight get in touch with and minimizing friction. The thickness and temperature level of the lubricant likewise play a substantial duty in friction decrease.

The 3rd element is the tons or stress related to the surfaces. Greater lots enhance the surface area call location and the rubbing force. Proper tons distribution and harmonizing are necessary to avoid extreme rubbing.

Furthermore, the rate of the relocating components, the product homes of the elements, and the ecological problems, such as temperature level and moisture, can likewise affect friction in machinery.

Benefits of Utilizing High-Quality Bearing Bushings

Utilizing top notch bearing bushings offers various advantages in terms of enhancing machinery performance and longevity. These advantages make purchasing high-quality bearing bushings a wise choice for organizations running hefty equipment.

One of the main benefits of using high-quality bearing bushings is reduced rubbing. Rubbing is a significant aspect that can result in tear and wear on machinery parts, causing reduced performance and increased upkeep prices. Top notch bearing bushings are created to reduce friction, permitting smoother procedure and minimizing the risk of damage to machinery parts.

Furthermore, premium bearing bushings add to improved efficiency. By lowering friction, these bushings help to maximize energy transfer within the machinery, causing enhanced productivity and minimized energy intake. This not only improves general performance yet likewise aids to reduce operational expenses in the long run.

Kinds of High-Quality Bearing Bushings

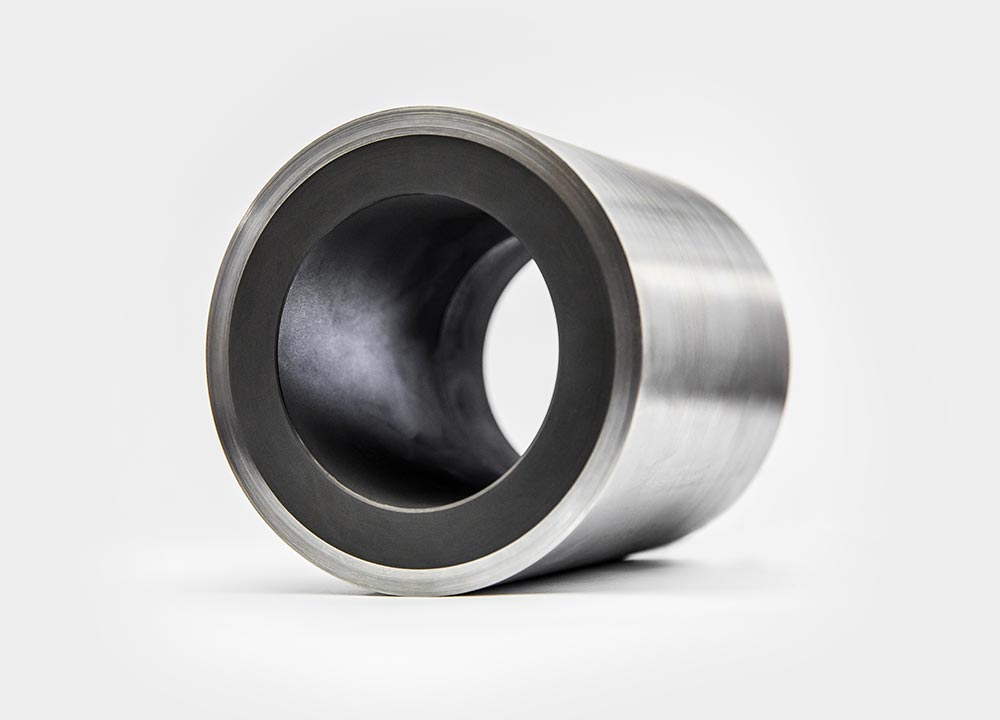

There are a number of unique varieties of high-grade bearing bushings readily available on the marketplace. Each type is made to satisfy particular needs and needs, making sure efficient decrease of friction in various applications. One preferred type is the simple bearing bushing, likewise known as a sleeve i was reading this bearing or journal bearing. This kind of bushing consists of a round sleeve made from materials such as brass, steel, or bronze, and it offers a low-friction interface between revolving shafts and stationary parts.

An additional type is the rolling component bearing bushing, which is typically made use of in applications where higher rates and heavier tons are entailed. This sort of bushing integrates moving elements such as rounds or rollers, which permit smoother and more effective turning.

Self-lubricating bearing bushings are also commonly made use of, particularly in applications where maintenance is hard or costly. These bushings are made of materials such as Graphite, nylon, or ptfe and have integrated lubrication homes, removing the demand for external lubrication.

Tips for Finding and Setting Up Bearing Bushings

One important factor to consider when selecting and mounting premium bearing bushings is to carefully review the particular requirements and applications, developing upon the knowledge of the unique types pointed out in the previous subtopic. To begin with, it is vital to understand the lots capacity and rate needs of the application. This will certainly help in identifying the suitable product and design of the bearing bushing to make certain optimal efficiency and longevity.

One more variable to consider is the operating atmosphere. Whether the bushings will certainly be exposed to heats, harsh chemicals, or extreme weather condition problems, it is vital to pick a material that can endure such problems without endangering its performance.

Moreover, the installment procedure plays a significant function in the efficiency of the bearing bushings. It is important to guarantee appropriate placement and fitment to stop any unnecessary anxiety or imbalance that can lead to premature failure. bronze bushing. Lubrication is likewise vital to lower rubbing and wear between the bushing and the rotating shaft

Lastly, routine evaluation and maintenance are needed to make sure the ongoing performance of the bearing bushings. This includes checking for signs of wear, keeping track of lubrication levels, and dealing with any type of problems quickly.

Final Thought

In final thought, top notch bearing bushings play a critical duty in lowering rubbing in equipment. By selecting and setting up the best kind of birthing bushings, the performance and efficiency of the machinery can be significantly improved. Factors such as worldly top quality, lubrication, and appropriate installation techniques all add to decreasing rubbing and making the most of the lifespan of the equipment. visit the site As a result, it is essential to purchase top quality bearing bushings to achieve optimum performance and longevity.

In this discussion, we will certainly explore the relevance of bearing bushings, the factors that impact rubbing in machinery, the advantages of utilizing high-grade bushings, and supply practical ideas for choosing and installing them. Allow us embark on this trip to discover exactly how high-quality bearing bushings can effectively lower friction and improve the efficiency of machinery.

Birthing bushings are made from products with low coefficients of friction, such as bronze or self-lubricating polymers, which aid to minimize this friction. High-grade bearing bushings are designed to lessen rubbing, allowing for smoother operation and minimizing the threat of damage to machinery components.